salt spray chamber calibration|salt spray testing parameters : online sales Salt spray testing is the process of testing and calibrating salt spray chambers to determine the corrosion resistance of different materials and coatings. . the key steps needed to properly . web3 de nov. de 2023 · Foto: Reprodução/Instagram. O ex-ator mirim Guillermo Hundadze, dono do canal ' Gui50 ', pronunciou-se pela primeira vez, nesta sexta-feira (3), após ser .

{plog:ftitle_list}

Resultado da Comparison between ARM Cortex-A78 and Qualcomm SM6375 Snapdragon 695 5G with the specifications of the processors, the number .

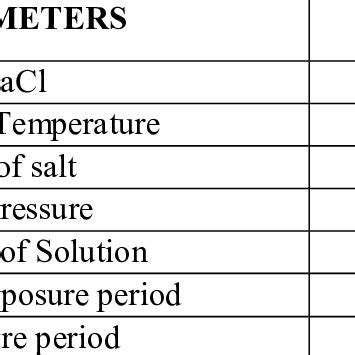

Chamber Calibration: Regularly calibrate the salt spray chamber to ensure that it operates within the specified parameters. This includes verifying the temperature, humidity, and salt fog distribution.Ascott salt spray chambers and cabinets – one of the world’s most modern and most versatile salt spray corrosion test systems – and with design, ergonomics and quality that’s in a class of its own. . •Large capacity floor standing salt .Corrosion test chambers can be used for Salt Fog, CASS, Humidity, Water Fog and many other test methods. Click for more information and full specifications. . Certification – Calibration traceable to NIST. Start Up Kit- 80cm 2 condensate . Salt spray testing is the process of testing and calibrating salt spray chambers to determine the corrosion resistance of different materials and coatings. . the key steps needed to properly .

salt spray testing parameters

salt spray temperature test

A salt fog test chamber, also known as a salt spray chamber or corrosion test chamber, is a controlled environment system specifically designed to simulate. . consider long-term expenses such as maintenance, calibration, spare parts, and technical support. Ensure that the supplier offers comprehensive after-sales services and support.This professional Salt Spray Chamber is designed and engineered offering the newest microchip technology combined with Analog Controls or a large Color Touchscreen Display, a homogeneous Salt Fog Distribution across all samples, a transparent Lid for sample monitoring, advanced Heating System with Infrared Temperature Monitoring, a high-speed .

Salt spray testing labs evaluate corrosion impact products and materials. At ATS, we perform salt spray tests to assess material resistance to corrosion. . as well as details on the chamber conditions, including pH and temperature. We can also provide the test chamber’s calibration and compliance data. Our Dedication to Quality. For more .

Ascott Salt Spray Chambers – one of the World’s most modern and most versatile salt spray corrosion test systems – and with design, ergonomics and quality that’s in a class of its own. Salt Spray Chambers to cover every testing requirement from continuous salt spray test through to condensation humidity and modified tests. Suitable for testing to popular standards including; .

Maintenance and calibration of salt spray chambers: To ensure accurate and consistent test results, corrosion chambers must be properly maintained and calibrated on a regular basis. This includes tasks such as cleaning the chamber, checking the solution concentration, and verifying the accuracy of the temperature and humidity controls. . A salt fog chamber, also known as a salt spray test chamber, is a climate testing equipment that simulates intense corrosive environments to evaluate corrosion and rust resistance of materials or products. A salt shower in the fog chamber simulates ocean environments or natural ways of corrosion attack to test durability levels of the products. In this article, we will go through the most effective methods for maintaining a salt spray test chamber so that it lasts for many years and delivers accurate findings. . Maintaining repeatable and accurate test conditions inside the chambers requires regular calibration of the chamber’s equipment and sensors. The accurate measurement and .

Timed canopy lock and purge of the cabinet interior with fresh air after testing and before the chamber is opened. Easily accessible salt spray atomizer(s) in transparent hard-wearing acrylic, for ease of maintenance. External portable salt solution tank for ease of cleaning. 73L for 450L Chambers and 90L for 1000L Chambers and above.

Corro-Salt for salt spray testing along with selected spares and consumables can be ordered online at www.ascottshop.com Calibration Usually carried out during scheduled service visits, Ascott service engineers offer instrument calibration traceable to International standards: Certificates of calibration will be provided. Submit a calibration request . Salt Spray Chamber Ventilation. To prevent back pressure within the chamber, it must be exhausted. When setting up the chamber, be sure to install a non-corrosive three-quarter-inch pipe from the exhaust chamber to a point outside the building. This exhaust should be as short as possible, straight, and gently .Each Salt Spray Test Chamber and Corrosion Test Chamber undergoes rigorous testing and calibration to ensure consistent and reliable results. These Test Chambers comply with the requirements of relevant national and international standards . A salt spray test chamber, offered by Pacorr, is an essential tool in the field of materials testing and quality control.This chamber is specifically designed to simulate and accelerate the process of corrosion in a controlled .

Corrosion Chamber Installation, Set-up & Calibration. Corrosion Testing Chamber expert with over 30 years of experience in installing, start-up, maintaining, training, and calibrating all types of cabinet manufacturers. . We work with Salt Spray, Cyclic Corrosion, and Salt Fog chambers. With our calibration services, we deliver accuracy in .The cyclic salt spray chamber is different from the basic salt spray test chamber. Cyclic corrosion test chamber exposes samples to a series of different environments in repetitive cycles that incorporate temperature, humidity, salt .This range of classic salt spray chambers are simple to set-up and run using the touchscreen controller. The specification table below outlines the standard chambers available alternatively any size or interior volume can be built to order.

salt spray humidity testing

Timed canopy lock and purge of the cabinet interior with fresh air after testing and before the chamber is opened. Easily accessible salt spray atomizer(s) in transparent hard-wearing acrylic, for ease of maintenance. External portable salt solution tank for ease of cleaning. 73L for 450L Chambers and 90L for 1000L Chambers and above.

Salt Spray Chambers are used in a variety of industries such as: aerospace, automotive, paint, coatings and rail. Options for many sizes of chamber including walk in for large and heavy components. Salt Spray Chambers Features: • Volumes: From 140 litres to 2.000 litres • Temperature range: From Room to +50ºCSubmit a calibration request . Use our filter below to find the chamber—including temperature-only chambers, temperature and humidity chambers, salt spray chambers, laboratory ovens, walk in rooms, and more—you need. Metric Imperial °C °F. Clear All Filters. Test Type.

An ASTM B117 salt spray test chamber is a specialized laboratory environment used to evaluate the corrosion resistance of metals in simulated outdoor environments. In other words, it’s a space where corrosion testing is conducted. Sometimes referred to as salt fog, a salt spray test is conducted in a closed chamber that can be adjusted to .

Salt Spray Chamber – Salt Spray Mode – How It Works Click on a component in the image or component name for more information This mode of operation is common to all Ascott salt spray chambers and is designed to meet the widest possible .All salt spray chambers and corrosion chambers offered by Labomat Essor. 1. Methodology. . The date of the renewal of the calibration should not coincide with the date of a test. The corrosion enclosure should be calibrated for the air temperature of the chamber as a minimum. If required, the following chamber components can also be calibrated: Regular Maintenance and Calibration: A salt spray test chamber will continue to operate at its highest level of performance so long as it is properly maintained and calibrated on a regular basis. By performing periodic cleaning, inspection, and calibration on the apparatus, we ensure that the test conditions remain consistent and accurate.Ascotts standard salt spray chamber with designation S.iS are available in 6 sizes, 120L, 450L, 1000L, 1300L, 2000L & 2600L. They are designed to run continuous salt spray tests conducted at a single user adjustable temperatures, such as ASTM B117, ISO 9227, JIS 2371 plus many more. . Calibration certificate; Consumables spares kit; Fallout .

Manufacturer of Salt Spray Chambers offered by Indeecon Equipments & Instrument Company, Thane, Maharashtra. Indeecon Equipments & Instrument Company. Vasai East, Thane, Maharashtra. . Table Top Wind Tunnel for Velocity Calibration; Dry Block Calibrators; Thermostat Test Bath; Ultra Low Temperature Calibration Bath (-80 degC) View More .

webBrazilian Porn Videos - Pornhub.com. Gay Only. All. Popular With Women. Verified Amateurs. Verified Models. Virtual Reality. 124,131. Amateur 412,820. Anal 112,727. Arab .

salt spray chamber calibration|salt spray testing parameters